|

HCL Gas Generation Unit Sulphuric Route

Product Details:

Product Description

Incepted with aim to gain maximum customer satisfaction, we are involved in manufacturing and exporting wide assortment of HCL Gas Generation Unit Sulphuric Route. Our products are highly appreciated and demanded for its international quality standard, high performance and low power consumption. We make use of quality certified material in designing our range to ensure its superior performance and long functional life at the clients' end. HCL Gas Generation Unit Sulphuric Route find exclusive usage in diverse industries and are highly acknowledged by the clients, spread across the country. Our efforts towards quality products have enabled us to get clients from across the country.

Other Details:

HCL Gas Generation Unit Sulphuric Route

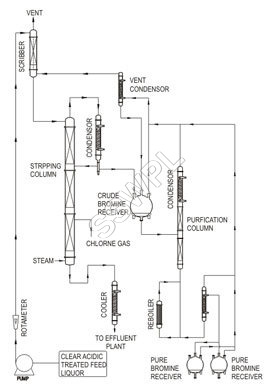

Various Dry HCl gas generation plant are supplied by 'Super' in a wide capacity range from 5kg./ hr. to 300kg./ hr.

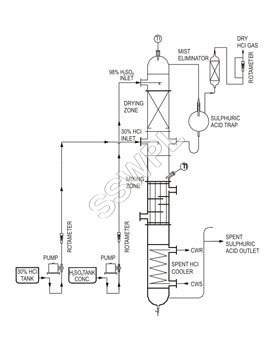

98% of Sulphuric acid and 30% Hcl are supplied to the Mixing Zone by the overhead tank or through metering pump depending upon the site height availability and customer requirement.

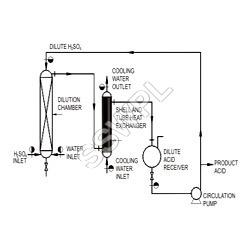

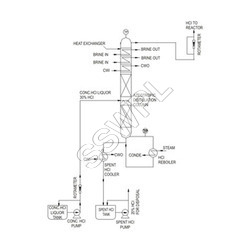

The H2SO4 feed and HCl are mixed before there entry inside the zone of reaction (Falling Film Tubular Heat Exchanger). Prior to discharge, the spent Sulphuric acid from the base of the Falling Film Tubular Exchanger is condensed in the Heat Exchanger. For the cooling operation, the Liquid Cooler uses cooling water.

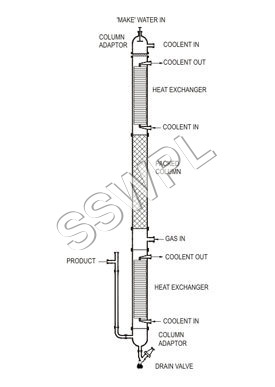

Falling Film Tubular Heat Exchanger generates the HCl gas which comes in contact with concentrated H2SO4 in the Dehydrating packed column or the Drying Zone. This zone is dedicated for the initial drying of the HCl gas. Sulphuric Acid trap is used to pass HCl gas from the top of the Dehydrating column to lower down the moisture percentage in HCl Gas.

With no moving parts in the overall system. The floor space requirements as well as utility need for the Plant are very less.

Process Packages

(One Stop Solution for All your Process Needs)

We deliver process packages in four major stages from initiation to completion which include designing, engineering, supply, installation and commissioning. In addition, as optional we also provide the same on turnkey basis as well with complete packaged instrumentation. Based on our vast experience of over three decades we strive to continuously bring new innovation in these packages to make them more efficient. We guarantee performance based on actual process parameters required by clients.

Other Products in 'Process Package Unit' category

|

SHIVA SCIENTIFIC GLASS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |